Context /Aims

According to the World Economic Forum, the construction industry currently accounts for about 6% of the world gross domestic product (GDP) and is expected to reach around 14.7% in 2030, which means that the construction sector plays a key role in any country’s economy in this sense the importance of construction automation has grown rapidly worldwide.

To achieve the desired level of automation, analogous to the Industry 4.0, breakthrough technologies have been adapted for construction applications and this transformation has been called as Construction 4.0.

RoBétArmé aims toward a step-change in the Construction 4.0 by automating particularly laborious construction tasks in all phases of shotcrete application. To this end RoBétArmé will deliver collaborative construction mobile manipulators, consisting of an:

- Inspection Reconnaissance manipulator (IRR) to address fast, high precision modelling and rebar reinforcement through metal additive manufacturing in the preparatory phase, and;

- A Shotcrete and Finishing mobile manipulator (SFR) to address autonomous shotcrete application and surface finishing during the construction and finishing phase, respectively.

Objectives

Develop a cognitive robot platform that address the complete chain of shotcrete application for autonomous construction, maintenance, and monitoring activities of infrastructures.

Develop an advanced high-precision and real-time infrastructure perception system through AI- enabled technologies and multimodal sensor fusion.

Develop cognitive and adaptable human-robot collaboration control schemes for dexterous execution of construction and maintenance tasks.

Release advanced modelling tools tailored to the Building and Construction Information Models for the fast and greener implementation of automated construction activities.

Develop cognitive Digital Twin and simulation environments for construction monitoring, diagnostics, and orchestration activities.

Commercialization and exploitation in application cases with economic impact in European construction industry.

Consortium

The Information Technologies Institute (ITI) was founded in 1998 as a non-profit organization under the auspices of the General Secretarial of Research and Technology of Greece, with its head office located in Thessaloniki, Greece. Since 10.3.2000 it is a founding member of the Centre of Research and Technology Hellas (CERTH), also supervised by the Greek Secretariat of Research and Technology. ITI is one of the leading Institutions of Greece in the fields of Informatics, Telematics and Telecommunications.

Since 1998 ITI has participated in a great number of Research and Development projects funded by European, Public investment funds and Services contracted by firms and other private legal entities. ITI’s research teams show their remarkable scientific work through a number of publications that includes scientific publications in international journals, publications in conferences, books and book chapters. ITI was evaluated by external Expert Committees in the area of Engineering, in 2002, 2005 and 2014 and received a grade of 9.65/10, 4.4/5 and 4.51/5, respectively.

The Institute has the infrastructure, the experience and the maturity to intensify its efforts on diffusing its research activities to key stakeholders and using all the necessary mechanisms and tools towards efficiently bringing novel or improved services and products to them through the Institute’s established spin offs. Specifically same actions have been made in the recent years through ITI’s collaborations with numerous Institutions in Greece and abroad as well as the founding of 7 new spin-offs.

DTU, the Technical University of Denmark, is an elite university with a global orientation and unique facilities, supporting outstanding education and research. DTU is an innovative university. We take responsibility for a knowledge- and fact-based society, with a commitment to sustainable development.We seek new, creative, and world-class partnerships with Danish and international researchers. In the quest for innovative solutions to societal challenges, we collaborate across academic disciplines. We promote a welcoming and collaborative educational and working culture, accommodating all with the requisite ability and drive.

The research and development activities for the RobétArmé project will be performed by the “Automation & Control” (AUT) Research Group, of the Department of Electrical & Photonics Engineering. AUT maintains multiple state-of-the-art robot lab facilities and focuses its research on autonomous robotic systems. AUT aspires to endow robots with perception and learning capabilities that will allow them to serve the society and industry. AUT has long experience in European and national Danish research projects in the areas of autonomous robotics deployed in industrial and agricultural environments.

The Ecole Polytechnique Fédérale de Lausanne (EPFL) is one of the two Swiss Federal Institutes of Technology and is located in Lausanne, Switzerland. EPFL ranks 14 in the top 20 universities worldwide (QS – Global World). The Learning Algorithms and Systems Laboratory (LASA) at the EPFL was founded on the 1st of January, 2006. LASA is led by Prof. Aude Billard, who has a long-standing expertise at developing robots and adaptive control architectures to realise skilful robot motions in a variety of robotic platforms. Research at LASA combines engineering, computer science and computational neuroscience methods for the development of learning control system to enable flexible human-robot interactions.

The LASA laboratory is composed of around 25 people with half PhD students, one third postdoctoral fellows and one third researchers and technicians. LASA was awarded more than 20 research grants from the European Commission, including an Advanced ERC grant. It also raised significant funding from the Swiss National Science Foundation, private foundations and the industry. It has led to the creation of two start-ups (Pomelo Tech in 2011 and AICA Tech in 2019).

The research at LASA focuses on the development of novel approaches in the field of robot control and machine learning. Such approaches enable robots to replan motion and force pattern to adapt to dynamically changing environments. Current efforts of the laboratory are dedicated to ensure that the robot’s motion remain safe for the robot’s embodiment, environment and humans. EPFL will lead the activities of WP5 on transferring skills from humans to robots. It will contribute to implement adaptive controller for motion generation and force adaptation to be used in the two real use cases.

KU Leuven is a leading higher education and research university ranking amongst the top 50 universities worldwide. Robetarme will receive support from KU Leuven's department of electrical engineering (group PSI) and its department of mechanical engineering (group RAM). The PSI group, the Center for the Processing of Speech and Images, is specialized in computer vision and its applications. The team has received several prizes for its work, including a David Marr award, two TechArt prizes, an EITC Technology Award, and a Henri Ford prize. It has a longstanding experience with European projects and ERC grants. Division RAM (Robotics, Automation & Mechatronics) deals with robotics research. It has generated multiple spin-off companies that are active in robotics-related activities, it has initiated several free and open-source software projects in robotics (Orocos, KDL, iTaSC), and it has participated in dozens of robotics and control oriented EU projects. The research group is a university core lab of Flanders Make (the strategic research centre for the manufacturing industry in Flanders).

SDU Robotics is at the core of the Odense Robotics Cluster involving 130+ startups and established companies in robotics. We are a team of currently ca. 65 researchers, specialized in robot solutions involving modelling, simulation and control of advanced robot technologies (systems and services) for industrial, welfare and medical applications. Our group is involved in a variety of national and European projects and features a strong network of academic and industrial partners. We solve challenging research problems derived from real-life challenges by implementing novel robot solutions. We value teamwork, professional diligence, enthusiasm for robotics and the drive to adopt new skills and extended responsibilities.

COBOD – Construction Of Buildings On Demand. World Leader in 3D Construction printing solutions. Continuously adding wider automation and robotics to construction. Our mission is to disrupt the global construction industry through world-class 3D automation. Faster. Better. Cheaper. We 3D printed Europe's first building in 2017. Subsequently, the first 2- and 3- story buildings in Belgium and Germany were made with our technology. Also, the first villa in Dubai and the first buildings in Africa have been printed by our 3D construction printers, like the first wind turbine bases. We have an open-source strategy, partnering with customers, academic institutions, and suppliers around the world. Our partners include General Electric (US), PERI Group (Germany), Dar Al Arkan (KSA), L&T Construction (India), JGC (Japan), and many more.

With our future printer systems, the printers can hardly be called just printers anymore – they will be multifunctional construction robots. Right now, we are working with the first movers. We are ahead of tomorrow’s norms and the big volume market. However, we will democratize 3D construction, making it accessible to all. Maturing technology and lowering risk – selling 3D robotics & automation solutions beyond first-movers and entrepreneurs.

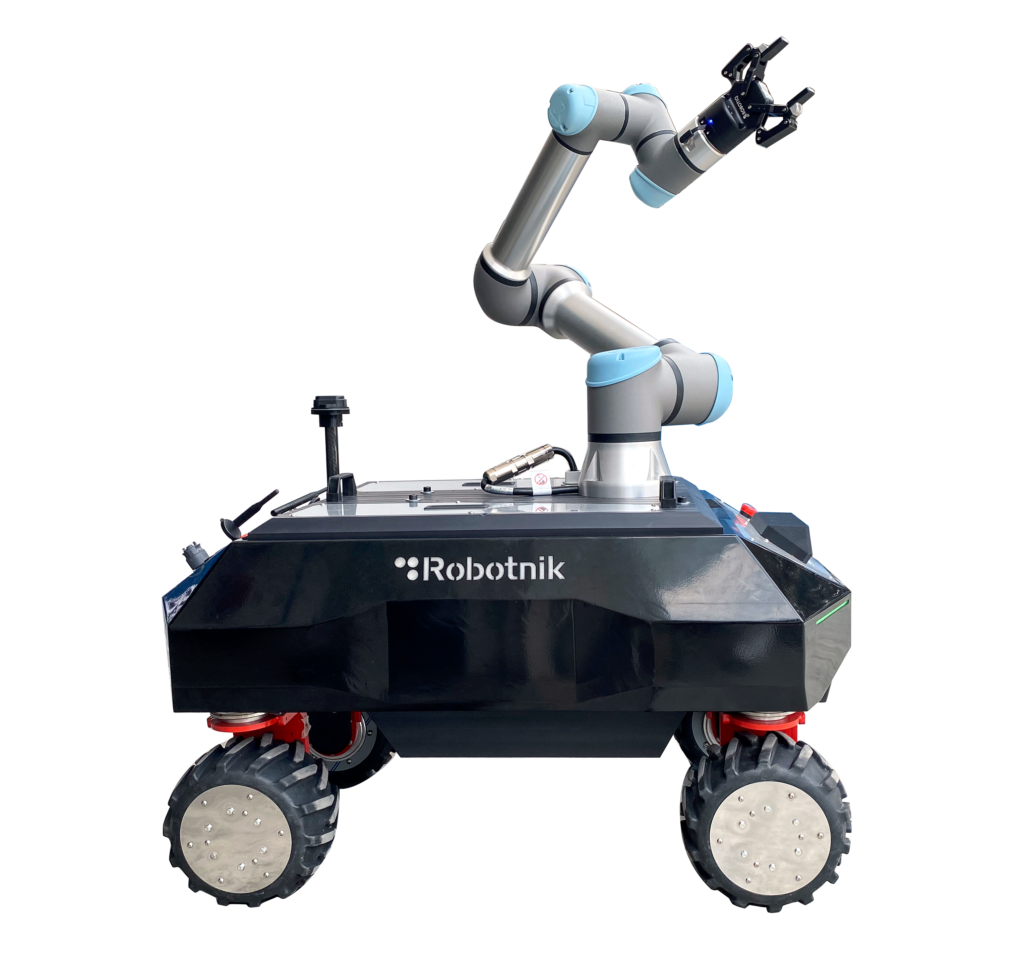

Robotnik is a company specialised in the development of mobile robotic platforms and leader in the UGV sector. The company has its own R&D department in mobile service robotics and a multidisciplinary engineering team qualified in various fields, such as manufacturing, industrial engineering, telecommunications and software development. After 20 years, Robotnik have experience in different fields and applications such as logistics, agriculture, inspection and maintenance or security and defense.

The direct connection between robotics R&D and the mobile robots and manipulators they have on the market allows them to offer the most intelligent and adapted solution for each project. Robotnik has participated in more than 60 research projects since its creation in 2002.

ANiMA est. 1991 is a company based in Greece, offering Additive Manufacturing equipment & services, 3D design software and Engineering Information Management solutions. Its mission is to promote the usage of innovative technology by striving to accelerate the adoption of AM in industry, with a 10 year goal to facilitate the integration of AM along with traditional manufacturing technologies. ANiMA’s aim is to provide the best additive manufacturing solutions for applications in growing markets that demand. The intent is to offer high quality equipment, for which they provide full local support, at a good price, utilizing open materials, that can produce high accuracy & finish final parts.

ANiMA has successfully installed hundreds of professional Additive Manufacturing systems for their customers and has been providing full after-sales support. The company has provided 3D CAD Software solutions with training and support for the manufacturing industry. Finally, ANiMA has been growing their Additive Manufacturing Service department, providing high quality parts using SLM, SLS, SLA and FDM technologies.

TITAN Cement Group is the largest cement and building materials producer in Greece and ranked among the top 20 producers globally (Global Cement 2017-2018). Founded in 1902, TITAN Group employs more than 5,400 people world-wide and is growing as a multi-regional, vertically integrated cement producer. In 2021 Group consolidated turnover was €1,715 million.

Currently, the Group operates eight cement production plants in Europe (Greece, Bulgaria, Albania, Serbia, FYROM, Kosovo) and six in other locations (USA, Brazil, Egypt, Turkey). Among TITAN's main tasks are GHG emission reduction strategies, valorisation of alternative fuels and raw materials, and the development of alternative cementitious materials. The portfolio of TITAN covers the production of cement, concrete, aggregates, mortars and other building materials; the transportation - distribution of products, and the processing and industrial utilization of fly ash.

TITAN Group’s CSR and Sustainability commitment is demonstrated in its own policies and practices as well as through active participation in international initiatives. TITAN was the first company in Greece to sign the United Nations Global Compact, which aims to safeguard human rights, labour rights, protection of the environment as well as combating bribery and corruption. It is a member of CSR Europe, of the World Business Council for Sustainable Development, of the Cement Sustainability Initiative and the European Alliance for CSR. It is also a member of the Global Cement & Concrete Association, the Portland Cement Association, in addition to national organizations in every country of activity.

At DigitalTwin Technology, we need to continuously strengthen our commitment to make ourselves more inclusive and to contribute to make our world more just. Where every great idea can be heard and where everybody belongs. Welcome to real-time digital twin: an access-all-areas look at ours unconventional journey from crazy idea of using game engine to implementing within serious industry solutions over past six rollercoaster years. Digital twins are emerging as the best way for enterprises to compound value from digital transformation initiatives. For the industrial enterprise, digital twin use cases are primarily being adopted across engineering, operations, and service – driving significant business value and laying the groundwork for digital transformation across the enterprise. Learn how developing a digital twin strategy can help you harness the convergence of the digital and physical worlds.

ICE is a specialist consultancy assisting partners improve their business activities through cutting edge research and innovation, custom software development, and commercial consultancy services. ICE specialises in handling and processing of data, coming from heterogeneous sources in multiple formats and different domains. Our specialised solutions enable enterprises to remain competitive in a rapidly evolving domains. ICE solution portfolio is composed of advance tools for master data management, business intelligence, process orchestration and analytics.

The available tools are offered as standalone services or as an integrated ICE Data Platform, which harnesses the strengths of open-source community to cater for varying needs of users across multiple domains. ICE is a specialist consultancy assisting partners improve their business activities through cutting edge research and innovation, custom software development, and commercial consultancy services.

ICE specialises in handling and processing of data, coming from heterogeneous sources in multiple formats and different domains. Our specialised solutions enable enterprises to remain competitive in a rapidly evolving domains. ICE solution portfolio is composed of advance tools for master data management, business intelligence, process orchestration and analytics. The available tools are offered as standalone services or as an integrated ICE Data Platform, which harnesses the strengths of open-source community to cater for varying needs of users across multiple domains.

Ingenieros Asesores is a company with more tan 30 years of history, made up of a multidisciplinary team of Engineers, Architects and technicians, who provide global solutions to the needs and demands of the Construction and Industry sectors. Our services include inspection and maintenance planning, physical simulation, IoT monitoring and profesional advice in a wide range of bussiness activities.

Digital Systems 4.0 delivers research-driven consulting projects in agile organisational structure, helping companies deliver their business goals through innovative digital transformation models and user-focused software. We are connected with scores of companies throughout Europe, working with blue-chip companies, innovative SMEs and trade associations to create value through innovation.

We apply user-centred software development and usability analysis to ensure adoption of software in knowledge-intensive domains including Industry 4.0 manufacturing and e-Health. Our experts have conducted user-centred design and useability evaluations in a number of EC-funded projects in manufacturing and services domains, and worked with blue-chip companies from the process industry to study the adoption of AI by R&D scientists. Our current projects include research on explainable AI to support the adoption of pathology detection solutions.

UNI – Ente Italiano di Normazione is the Italian Standardization body, a private, non-profit association, founded in 1921 to develop, approve and publish standards in all economic sectors (industry, trade and services) excluding electric and electrotechnical ones. UNI defines and develops voluntary standards in relation to various kinds of products, materials, services and processes paying attention to the environmental, economic and social sustainability.

UNI is the official Italian member of CEN (European Committee for Standardization) and ISO (International Standard organisation) as acknowledged by the EU Reg. N. 1025/2012 and the Italian law D.L 223 of 15/12/2017. The standardization activity is carried out by technical committees to which representatives of all subjects in the concerned supply chain are invited to participate. The process is designed to guarantee specific standards’ underpinnings: consensus, democracy, transparency, voluntariness. It is for these characteristics that standardization can bridge the gap in economic and social sectors without any reference laws, while easing the regulation framework.

At European level, the use of harmonized technical standards represents presumption of conformity to the essential safety requirements of products with CE marking allowing their free circulation on the internal market. Moreover, in order to contribute to broadcast technical knowledge, UNI carries out also customized education activities, organizing trainings, webinars, events, … In line with CEN “Integrated Approach” strategy, UNI promotes standardisation as a tool to bridge the gap between the innovation and the market, boosting knowledge transfer, coordination and confront among all actors in the supply chain, while integrating from the beginning standardization in R&I projects.

In particular, UNI Innovation and Development department actively participates to international and national R&I projects and elaborates “Prassi di Riferimento” (UNI/PdR): voluntary, bottom up pre-normative standardization documents available free of charge aiming at codifying innovative market and technology best practices as basis for future standards.In parallel, the Innovation and Development Department contributes also to CEN Workshop Agreement (CWA) at EU level, documents designed to meet a market need where an innovative technology has not reached a sufficient degree of stability for the development of a European Standard.Always to boost innovation through standardization, in the last years UNI Innovation and Development Department has also been involved as partner in several European projects.

The More Collaborative Lab is a private non-profit association that aims to be a link between the scientific knowledge produced in academic and scientific institutions and the business community. MORE prioritizes the transfer of knowledge and technology from research and innovation centers in mountain areas to companies in order to create economic, social and cultural value in the regions involved. MORE focus on the enhancement of by-products of the agro industry; Sustainable agriculture and forestry; Preservation of cultural heritage and territorial enhancement; Clean, efficient energy and intelligent technology. More is currently establishing strategic partnerships with industrial partners focusing on closing the gap between research results and companies.

The European Factory Foundation (EFF) is a non-profit association of research and industry organisations from manufacturing, logistics and ICT sectors. Established by 12 founding members in 2019 in Vienna (Austria), the EFF is an independent body, providing platform components for multi-stakeholder interactions and collaborations. Through its ecosystem, the Portal, Marketplace and Data Spine, the EFF promotes the development and uptake of innovative solutions from Industry 4.0, Internet of Things, Artificial Intelligence and Big Data domains.

With 52,800 responsible and committed employees in more than 60 countries, Bouygues Construction designs, builds and operates projects in the sectors of building, civil works and energies and services. A leader in sustainable construction, the Group sees shared innovation as its primary added value and ensures that health and safety are its top priorities. It has pledged to cut its greenhouse gas emissions by 30% by 2030 and offers its customers a wide range of low-carbon solutions. In 2020, Bouygues Construction generated sales of €12 billion.

Bouygues Construction's value chain consists of eight stages: land management and urban planning, financial engineering, usage analysis, design and technical engineering, construction, maintenance and operation, user services and dismantling. From upstream to downstream, our teams carry out projects of all sizes in three sectors: infrastructure, industry and construction. We combine the best expertise and innovations, at the service of the areas in which we work, always drawing inspiration from the greatest success stories.

Arup was born of our founder’s conviction that a more collaborative and open-minded approach to engineering would lead to work of greater quality and enduring relevance. Sir Ove's legacy is an organisation that continues to be recognised for bravely imaginative solutions to the world’s most challenging projects. For over 75 years, Arup has been a place where creative people can develop their talents, collaborate with likeminded colleagues and produce incredible work. From Ove’s founding interest in function and beauty, to today’s urgent need for a more sustainable built environment, discover the many different ways we continue to shape the modern world.

Our people are independent by nature, with the confidence to take on some of the world’s most challenging projects. For over 75 years we have nurtured pioneers and original thinkers, becoming a welcome home for the creative and ambitious. From concert halls that set new standards of acoustic detail to designing the physical connections between nations, ours is a story of relentless innovation.

Maintaining its founder’s individuality and spirit, Arup today is a place where talented people can pose difficult questions and chart a better course. Owned by its members, the organisation’s commercial independence underpins its commitment to developing sustainable development outcomes across the built environment.

Christiansen & Essenbæk A / S is an independent limited company with a turnover of DKK 200 million. and currently employs 150 hourly-paid employees and a staff of 30 salaried employees. The company is 100% owned by Murersvendenes Finans A / S. Since its founding in 1971, Christiansen & Essenbæk has developed into one of the leading companies when it comes to concrete renovation, concrete maintenance and injection - just as we have great expertise in traffic regulation, demolition, diamond cutting and construction concrete.

As a construction company in the area, our experience ranges widely from the public to the private sector with renovation and maintenance of bridges, tunnels, port and industrial facilities, swimming pools, schools, institutions and residential buildings, etc. Our extensive experience base combined with extensive know-how and highly competent employees has given us the opportunity to develop new working methods and processes for repair, prevention and maintenance of concrete structures. With these properties, we are well prepared to solve the renovation tasks of today and the future.

Whether we perform small or large tasks, ranging from subcontracting tasks to project management in turnkey contracts, the task is carried out with the highest degree of professional competence, just as good collaborative relationships are strived for our partners, both professionally and humanly. Implementation of a project takes place through the use of good, loyal and well-trained employees, good quality management, as well as the best and most modern equipment for the task. Christiansen & Essenbæk A / S carries out contracts throughout Denmark as well as in Greenland and the Faroe Islands.

Fellow Projects

RoBétArmé , BEEYONDERS, Reincarnate, HumanTech, BIM2TWin, Reconmatic and Incube have joined forces and formed the Tech4EUconstruction cluster. Funded by the European Commission, the cluster members aim to develop and demonstrate new technologies to further digitalize and automatize the European construction sector, targeting to increase its safety and attractivity for workers.

Finally, the cluster seeks to stimulate the EU’s sovereignty in the industry, decreasing the need for technological imports.

Have a look at our fellow projects’ websites and follow our hashtag #Tech4EUconstruction to stay tuned on the cluster’s latest activities and news.